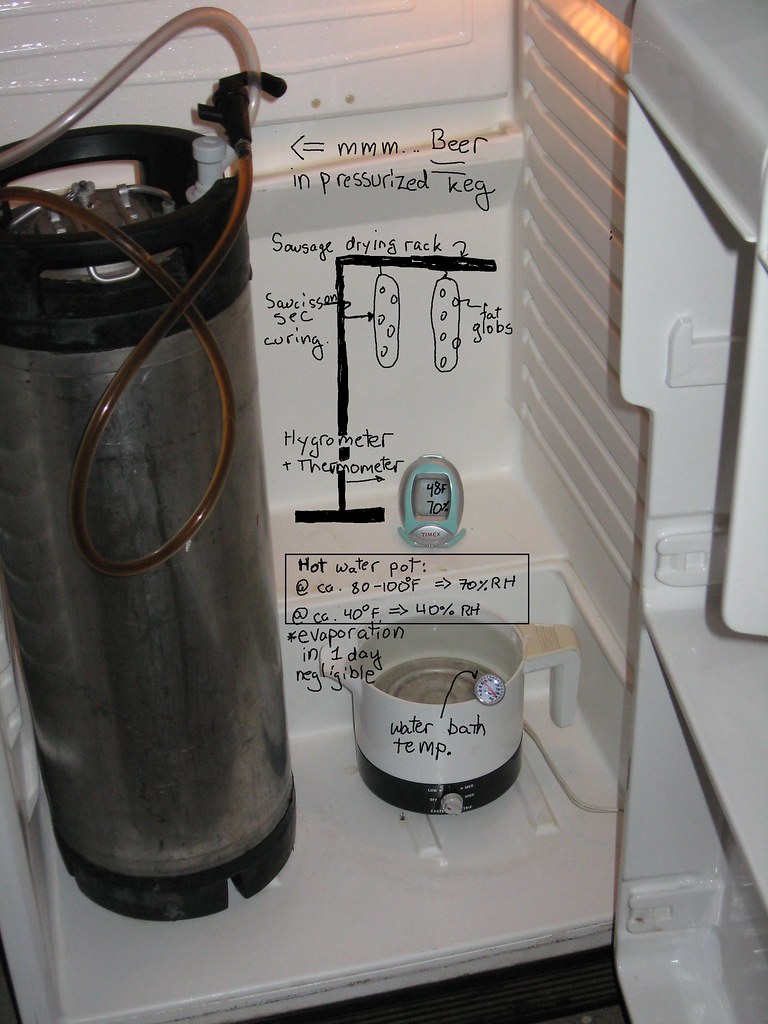

(Click image for much better view)

Before tackling Ruhlman's saucisson sec, I needed a place for the sausage to undergo curing for about 3 weeks at 50°F and at least 60% relative humidity (RH). My beer fridge usually only has a single keg in it and I decided to tweak this chamber a bit to see if I could achieve a steady temperature/RH.

Baseline for the beer fridge is 45°F and 30-35% RH. Too dry. I thought some water in the bottom might increase the humidity. It did, to about 40%. After a number of different substrates placed in the fridge failed, I thought about increasing the water temperature by using a variable temperature hot pot. It's not a trivial problem. The fridge has a thermostat, the hot pot at a higher temperature will cause an increase in the vapor pressure of the water resulting in a higher humidity and finally the interdependence of the temperature and relative humidity make this environment nearly impossible to predict or calculate outcomes.

Empiricism to the rescue. I was able to fine tune both the fridge setting and hot pot setting to achieve the following boundary conditions:

38-40°F/40%RH with the hot pot on lowest setting (off)

48-50°F/68-70%RH with the hot pot at 90°F.

Also, at 90°F, the water barely evaporates over the course of 24 hours.

I have to have that kind of flexibility because of what Andrew warned me of. When the fresh sausage goes in for a cure, it loses water over time, thus increasing the humidity inside the chamber. Consequently, I need to be able to decrease the humidity contributed by the water bath to maintain a constant interior RH as the sausage cures.

I have some long term monitoring to do to validate the setup, but I'm confident enough, and the sausage ingredients are inexpensive enough to take a stab at it. Andrew, I may take you up on your generosity of the sausage stuffer loan, I can't wait any longer.

Beer Keg and Sausage, how can it get any better. Paul Bertolli built his own little cave. I think your approach is a lot more economical. I hope to start making salumi in the near future. Thanks for the idea.

ReplyDeleteI am having fun making sausage. We have Pork Shoulder on sale all the time in the Bay Area.

Totally Random. After spending months trying to figure out how to obtain constant humidities at a variety of temperatures for my doctoral research (and having filled many a heated humidity reservoir), I strongly suggest checking out salt solutions. For instance, standard table or road salt reliably gets about 75%RH at a variety of temperatures.

ReplyDeleteHey Steph,

ReplyDeleteYeah, those doctoral thingies are pretty useful, eh? I got one some years ago.

The problem isn't getting UP TO 75% but the ambient temp in the basement is, at times, greater than that. A small slurry of salt/water isn't going to decrease the RH in a large volume of moist air appreciably. This is complicated by the fact that I need my environment slightly opened to have an air volume exchange once in a while. So, I'm working with a semi-open container. In the winter, when RH is much lower, the NaCl slush would be perfect. In summer, I might have to go with a NaBr slurry or even CaCl2. Still working on it. It's hardly random, just challenging.